Since 2017, the solid-state hard drive industry has frequently exposed problems such as copycats and black cores. Many copycat manufacturers use black solid-state hard drives in order to obtain greater benefits, but consumers do not know what is black solid-state hard drives.

So today, the author from the technical level for everyone to read about the meaning of the three terms flash memory particles.

SSD flash memory particles explain: only recognize the original factory, black / white film do not touch

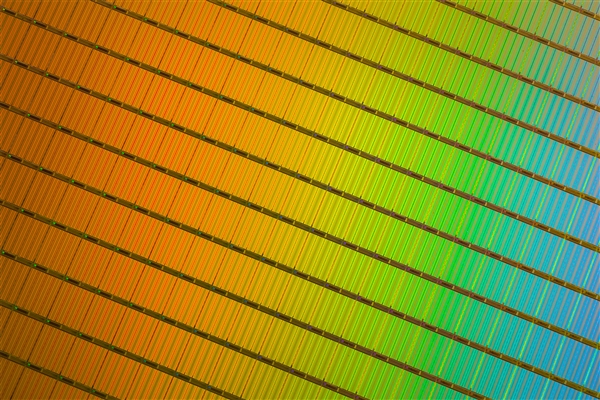

Wafer wafer

First of all, we need to understand how granules in SSDs come from.

In simple terms, a manufacturer who owns a production wafer produces a complete wafer. The wafer consists of pure silicon (Si) and is generally divided into 6-inch, 8-inch, and 12-inch sizes. The wafer is produced on a wafer basis. of.

A small piece on the wafer is a wafer wafer body. The scientific name is die, and it becomes a particle after packaging, which is the Nand Flash chip in our SSD.

SSD flash memory particles explain: only recognize the original factory, black / white film do not touch

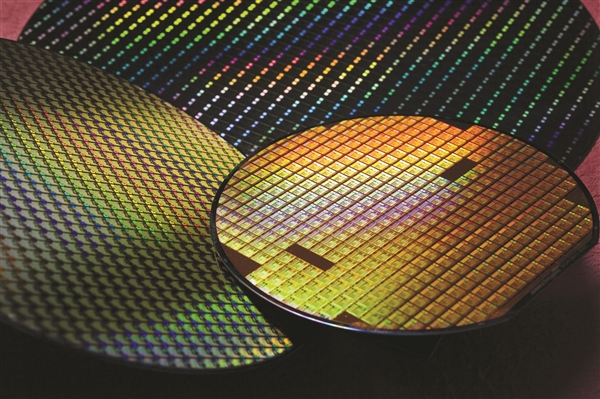

The shape of a whole wafer, the inside square is die.

The wafers are first cut, then tested, and the intact, stable, full-capacity die is removed and packaged to form a daily-viewing Nand Flash chip.

Then, the remaining on the wafer, either unstable or insufficient capacity, or partially damaged or completely damaged. The original factory will consider the quality assurance and declare the die to be dead. It is strictly defined as the scrap disposal of all waste products.

Normally, a wafer is inspected, a qualified die is removed, and then it is packaged into flash particles in a solid state drive. This is what we call the original film. Then the unqualified die is left and we call it black. The price of the original film is very high, while the price of the black film as a scrapped item is very low. Generally, the unscrupulous manufacturers purchase the black film is calculated in tons.

What is "white film" then?

In fact, the white film is detected in the original film after the encapsulation of particles, and then eliminate the garbage. Genuine NAND cannot have white film.

Therefore, black and white films are actually scraps produced in the process of chip manufacturing. Black films are the parts that are eliminated at the raw material stage. White films are unqualified products that are detected after finished products.

In terms of quality, the black NAND is very bad, because the original factory has already sentenced it to death, but the downstream plant sold it after reducing its capacity, that is, castration, but the quality is still poor, and the purchase of such particles is also Equivalent to gambling.

For this reason, users are advised to pay attention to original products when purchasing solid-state drives. First of all, they themselves are upstream original manufacturers. They have the ability to produce and process wafers and have exclusive advantages in Flash materials. Secondly, stability is the first choice for master selection. After all, SSDs store user data and are not sloppy.